Same environmental protection technology

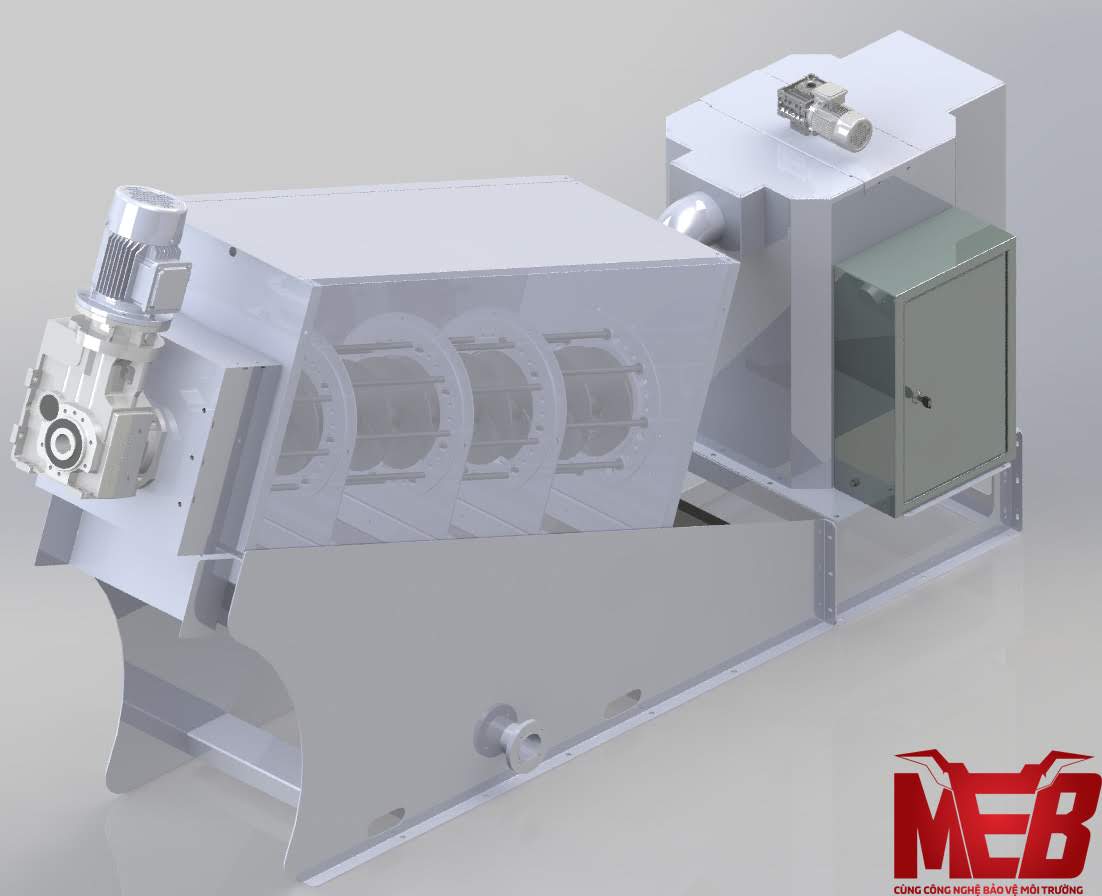

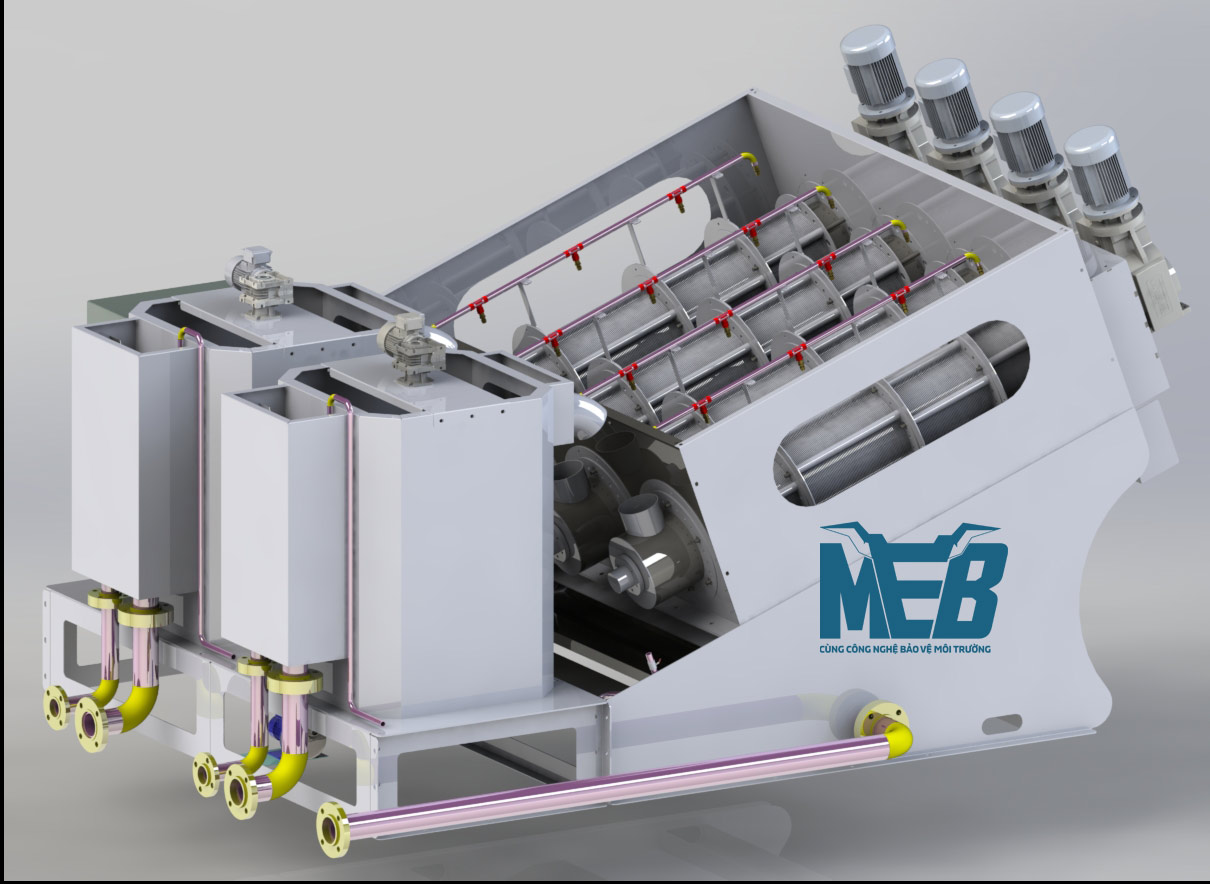

Screw sludge presses

Manufacturer: MEB CORP

MODEL: MODEL-001

Power range: 0.12 – 55 Kw.

Torque range: 27 – 14,000 Nm.

Ratio range: 0.8 – 8600

Screw sludge presses

Screw technology used in sludge treatment is quite new in the Vietnamese market

MEB Company has bravely researched and succeeded in producing screw sludge presses with wide capacity range, from 0.5m3 – 20m3 / h, serving factories with different sludge treatment scales.

-

What is Screw sludge presses?

The machine is designed based on the principle of screw conveyor in continuous operation, which is a combination of movable and fixed discs to create enough clearance for water to be separated from the mud.

Image description:

When the wastewater is loaded into the tank, the screw is in charge of transport and rotates and presses the ingredients together to squeeze the water until the raw materials stick to residue and dry completely, the screw will push the raw material this time. pass through the slot of the load screw to fall out according to the catcher installed at the outlet end of the machine

-

Principle of operation

Separating sludge from water, the drier the sludge, the easier it is to transport and handle.

The sludge is pressed directly from the sedimentation tank / from the DAF / from the garbage comb / or sludge tank.

Illustrating images:

-

What sludge is suitable for the screw presses?

– Organic sludge such as: sludge from food processing, aquaculture sludge, livestock sludge, sludge from domestic water treatment system.

– Inorganic sludge such as textile and dye sludge, paper mill sludge, plating sludge, resin sludge, cosmetic mud, ceramic mud

-

Classification of screw sludge presses::

2 Type include: 100% INOX-SS304 AND 50% Inox + 50% ODPS

Refer to the type of production to invest in the right machine

| Mud type | 100% SS304 | 50%SS304-50% ODPS | Why to chose this model |

| ORGANIC: food sludge, oily sludge, seafood sludge … | Good | Usually high alkalinity, containing oil and grease, using 100% stainless steel for low humidity in the sludge, high durability when the device is used for a long time. | |

| INORGANIC: Textile dyeing, plating | Good | Good | 100% Inox SS-304: high strength, drier sludge (humidity 30-60%), high price

Inox SS-304 and 50%ODPS , drier sluge 45-75%, good price |

| NEUTRAL: sludge from water company | Good | This mud contains silt, fine sand, so the use of a combination resin should be used to reduce the friction between the screw blade and the screw, ensure the machine runs durable and achieve sludge separation | |

| Other sludge such as: plating sludge, paper sludge, sludge from resin company, microbiological mud | Depending on the desired humidity, investment costs to choose the right machine |

- Capacity of sludge presses

| STT | Model | Công suất (m3/h) |

Dài (mm) |

Rộng (mm) |

Cao (mm) |

Khối lượng (Kg) |

||

| 0,2% | 2% | 5% | ||||||

| 1 | MEB-161 | ~ 6 Kg-DS/h (~ 3 m3) |

~ 20 Kg-DS/h (~ 1 m3) |

~ 40 Kg-DS/h (~ 0.8 m3) |

2340 | 680 | 1600 | 360 |

| 2 | MEB-162 | ~ 12 Kg-DS/h (~ 6 m3) |

~ 40 Kg-DS/h (~ 2 m3) |

~ 80 Kg-DS/h (~ 1.6 m3) |

2510 | 1090 | 1600 | 620 |

| 3 | MEB-211 | ~ 12 Kg-DS/h (~ 6 m3) |

~ 40 Kg-DS/h (~ 2 m3) |

~ 80 Kg-DS/h (~ 1.6 m3) |

2770 | 730 | 1740 | 510 |

| 4 | MEB-212 | ~ 24 Kg-DS/h (~ 12 m3) |

~ 80 Kg-DS/h (~ 4 m3) |

~ 160 Kg-DS/h (~ 3.2 m3) |

3010 | 1190 | 1740 | 880 |

| 5 | MEB-271 | ~ 15 Kg-DS/h (~ 7.5 m3) |

~ 60 Kg-DS/h (~ 3 m3) |

~ 120 Kg-DS/h (~ 2.4 m3) |

3270 | 830 | 2000 | 740 |

| 6 | MEB-272 | ~ 30 Kg-DS/h (~ 15 m3) |

~ 120 Kg-DS/h (~ 6 m3) |

~ 240 Kg-DS/h (~ 4.8 m3) |

3510 | 1330 | 2000 | 1330 |

| 7 | MEB-273 | ~ 45 Kg-DS/h (~ 22.5 m3) |

~ 180 Kg-DS/h (~ 9 m3) |

~ 360 Kg-DS/h (~ 7.2 m3) |

3570 | 1840 | 2000 | 1850 |

| 8 | MEB-274 | ~ 60 Kg-DS/h (~ 30 m3) |

~ 240 Kg-DS/h (~ 12 m3) |

~ 480 Kg-DS/h (~ 9.6 m3) |

3510 | 2340 | 2000 | 2310 |

| 9 | MEB-351 | ~ 40 Kg-DS/h (~ 20 m3) |

~ 100 Kg-DS/h (~ 5 m3) |

~ 200 Kg-DS/h (~ 4 m3) |

3730 | 930 | 2170 | 1080 |

| 10 | MEB-352 | ~ 80 Kg-DS/h (~ 40 m3) |

~ 200 Kg-DS/h (~ 10 m3) |

~ 400 Kg-DS/h (~ 8 m3) |

4020 | 1540 | 2170 | 2010 |

| 11 | MEB-353 | ~ 120 Kg-DS/h (~ 60 m3) |

~ 300 Kg-DS/h (~ 15 m3) |

~ 600 Kg-DS/h (~ 12 m3) |

4020 | 2470 | 2170 | 3100 |

| 12 | MEB-354 | ~ 160 Kg-DS/h (~ 80 m3) |

~ 400 Kg-DS/h (~ 20 m3) |

~ 800 Kg-DS/h (~ 16 m3) |

4020 | 3070 | 2170 | 4020 |

| 13 | MEB-401 | ~ 60 Kg-DS/h (~ 30 m3) |

~ 160 Kg-DS/h (~ 8 m3) |

~ 325 Kg-DS/h (~ 6.5 m3) |

4110 | 1030 | 2550 | 1350 |

| 14 | MEB-402 | ~ 120 Kg-DS/h (~ 60 m3) |

~ 320 Kg-DS/h (~ 16 m3) |

~ 650 Kg-DS/h (~ 13 m3) |

4530 | 1720 | 2550 | 2690 |

| 15 | MEB-403 | ~ 180 Kg-DS/h (~ 90 m3) |

~ 480 Kg-DS/h (~ 24 m3) |

~ 975 Kg-DS/h (~ 19.5 m3) |

4530 | 2750 | 2550 | 4030 |

| 16 | MEB-404 | ~ 240 Kg-DS/h (~ 120 m3) |

~ 640 Kg-DS/h (~ 32 m3) |

~ 1300 Kg-DS/h (~ 26 m3) |

4530 | 3440 | 2550 | 5360 |

Manufacturer information

Product catalog

quality

genuine

to take place

transactions